Processing organic waste in 24 hours

MISHIMAX®

organic waste volume reduction system

Reduce the volume of food scraps and other organic

waste by 90% or more using high processing capabilities

Produced by

Mikuniya Corporation

- Top page

- Innovations from Shimane

- MISHIMAX®

Issues in Industrial Waste Disposal

Processing decomposing waste that contains moisture poses technical challenges that even local authorities face difficulties resolving. The same applies to the increasing volume of industrial waste from economic development and the surge in household waste driven by population growth.

Introducing equipment to process industrial waste is not only costly but also takes effort to maintain and manage. At the same time, companies are being called upon to achieve the SDGs. The issue of organic waste has long been a persistent challenge, troubling people throughout history.

MISHIMAX, powered by Mikuniya Corporation,

solves organic waste

disposal challenges

- MISHIMAX uses wood chips and microorganisms to enable high-speed processing of food waste, sewage sludge, and other organic waste.

- MISHIMAX helps reduce disposal costs by eliminating labor and costs associated with waste collection and transportation.

- MISHIMAX equipment is customizable to meet varying capacities and regional needs with flexibility.

- MISHIMAX also supports the SDG initiatives of companies aiming for a resource-recycling society.

What is the MISHIMAX Organic Waste Volume Reduction System?

MISHIMAX is a revolutionary device that uses high-temperature aerobic fermentation technology with indigenous bacteria to reduce the volume of organic waste by approximately 90% in 24 hours.

MISHIMAX is operable anywhere indigenous bacteria thrive, using naturally occurring microorganisms to ferment and decompose waste. The system is available in most countries and regions worldwide, excluding extremely cold and polar areas. Inspections at public testing facilities and proof-of-concept experiments using in-house equipment demonstrated the quality and performance of MISHIMAX equipment, while operational tests in diverse temperature conditions further confirm its durability.

MISHIMAX currently meets the needs of a wide range of small businesses, including cafeterias and restaurants, as well as medium- and large-scale businesses, such as food processing plants, livestock farms, and water treatment facilities.

Why Choose MISHIMAX?

1.MISHIMAX uses wood chips and microorganisms for high-speed processing

The key to the high processing capacity lies in our uniquely developed wood chips.

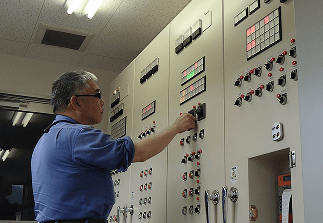

The MISHIMAX fermentation and decomposition tank structure is designed to ferment and decompose waste with microorganisms, using wood chips made from thinned timber in the process.

Cavities in the wood chips absorb solid organic matter where microorganisms ferment and decompose the matter into carbon dioxide, water, and ammonia.

This system flow reduces food waste and livestock manure volumes by more than 90% in just 24 hours. MISHIMAX can process between 25 kg to 15 tons per day.

2.MISHIMAX offers excellent cost performance and reduces processing costs

MISHIMAX only requires users to dispose of post-treatment residue once every six months. Wood chip replacement occurs at the same six-month interval, significantly reducing labor and operational costs.

The residue not only contains fertilizer components like nitrogen and phosphorus, making it suitable as microbial fertilizer, but the remaining wood chip fibers also offer potential for use as biomass fuel.

3.MISHIMAX offers customizable equipment capacities tailored to meet regional needs

Smaller machines (those that process under 50 kg/day) are manufactured on consignment in Vietnam and can be customized to suit the specific conditions of each country or region. Mikuniya is steadily expanding our sales channels in Japan and internationally. We are establishing a legal entity in Vietnam, broadening operations across Southeast Asia, and negotiating with potential distributors in the region.

4.MISHIMAX supports the SDG initiatives of companies striving to create a resource-recycling society

MISHIMAX eliminates the need for waste collection, transportation, and incineration, thereby reducing greenhouse gas emissions associated with these processes. A local government simulation proved these effects, demonstrating that MISHIMAX could reduce greenhouse gas emissions by as much as 62%.

Mikuniya launched an agricultural business that uses residues as fertilizer to produce crops. The company farm on Daikonjima Island in Matsue City, Shimane Prefecture is home to a thriving abundance of crops. Mikuniya believes our active involvement in the post-recycling agriculture business will allow us to offer convincing proposals and technologies to address SDGs and build a resource-recycling society.

Public and Private Sector Facilities Operating MISHIMAX (Partial List)

・Various public and private facilities use MISHIMAX. Uses include volume reduction (fertilization) systems at purification centers and volume reduction systems at school lunch centers.

The company also engages in research and development and conducts joint research with universities.

・Shimane University – Initiatives promoting the use of fungal fertilizers and organic resources

・Shimane Institute for Industrial Technology – Research on the development of the physical structure of wood chips

・Da Nang University of Technology and Kyoto University – Proposal and application of efficient volume reduction technology for organic waste in Da Nang, Vietnam (*collaborative research with both universities)

・And many more

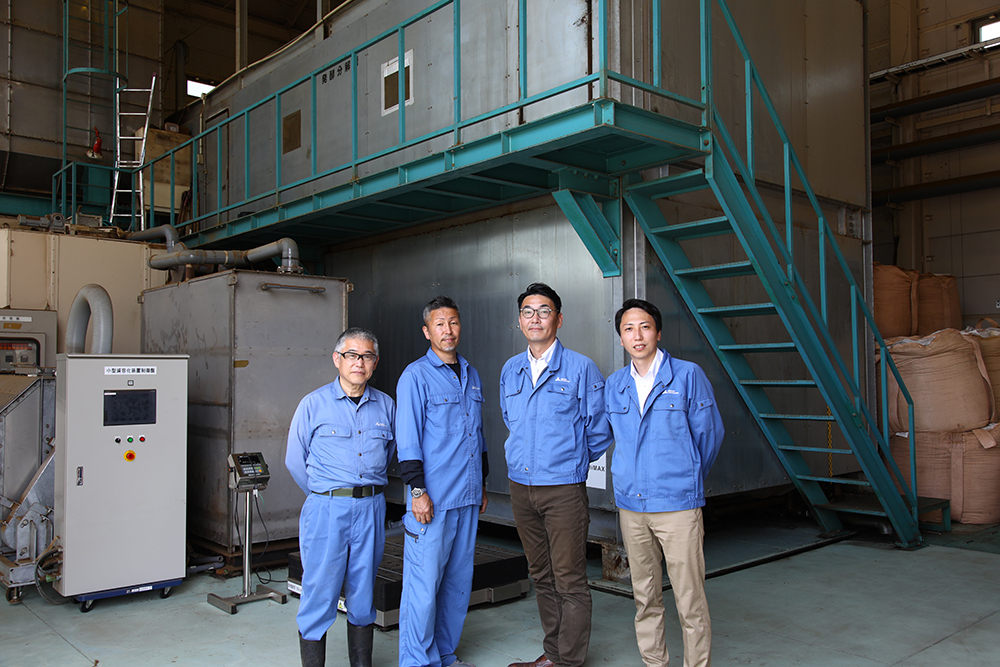

Proud Manufacturer: Mikuniya Corporation

Delivering multifaceted consulting to build a resource-recycling society

Mikuniya Corporation focuses on risk consulting for disaster prevention and environmental management.

The sustainable use of limited resources and energy has become a fundamental expectation in recent years. That's why Mikuniya is dedicated to supporting the creation of a resource-recycling society.

MISHIMAX, born from joint research with Shimane University, embodies our core principles.

We are committed to sharing MISHIMAX with future generations and expanding its reach worldwide.

Click photos to enlarge

Company profile

| Company name | Mikuniya Corporation |

|---|---|

| Home page | https://www.mikuniya.jp/mikuniya_eng/ |

| Outline of business | Sales of organic waste volume reduction equipment and circular

filtration systems; consulting services for waste and water treatment |

| Date of establishment | 1985 |

| Capital | 10 million yen |

| Number of employees | 195 |

For inquiries, please contact Overseas Expansion Support Office, Shimane Prefectural Government: kaigai-tenkai@pref.shimane.lg.jp

Headquarters

Headquarters

1-403-35 Kosugi-cho, Nakahara-ku, Kawasaki-shi, Kanagawa

Prefecture

Musashi Kosugi Tower Place

Shimane Office

2930-6 Shobara, Hikawa-cho, Izumo-shi, Shimane Prefecture

Asahi Himawari Kobo

362-45 Hongo, Asahi-cho, Hamada-shi, Shimane Prefecture

Nakaumi Office

151-1 Mawatashi, Yatsuka-cho, Matsue-shi, Shimane Prefecture