Paint that functions as both primer and topcoat

AMI COAT

Compatible with a wide range of surfaces

Highly durable, heat-reflective paint that shortens work schedules

Produced by

Matsue PaintCo., Ltd.

- Top page

- Innovations from Shimane

- AMI COAT

Struggling with paint applications?

Want more affordable heat-reflecting paint

Need more durable protection for your building

Painting high areas too risky

AMI COAT by Matsue Paint is a functional paint that solves these and other common problems.

- Finish most projects in one coat with our three-in-one formula combining primer and finish

- Skip priming separate composite materials with this one-step product

- Prevent heat stroke and reduce cooling expenses with advanced heat reflection

- Protect surfaces from harsh environments with our formula, nearly twice the thickness of ordinary paints

- Finish early with our one-step painting process; save time and reduce the risk of working on high areas

- Reduce administrative, transportation, and other unnecessary costs through shortened work schedules

Advantages of AMI COAT

1.Three steps in one

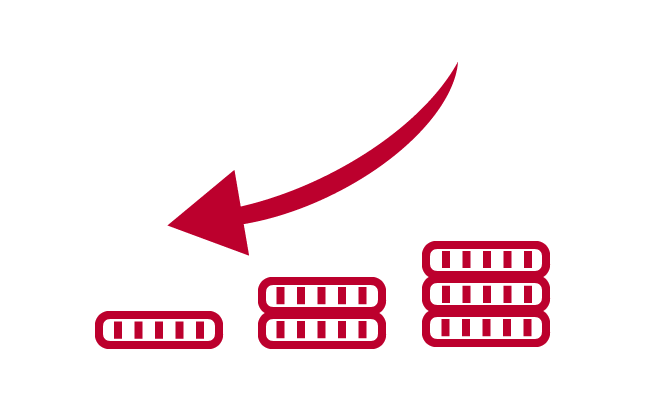

Our innovative AMI COAT paint reduces labor hours by integrating adhesion and durability. While conventional painting processes require three coats, AMI COAT covers a wide range of surfaces in only one coat.*

Moreover, one coat of AMI COAT is twice as thick as three coats of conventional paint. Our secret is the ingredients. We successfully combined three special materials that work together to form a tough paint.

- *You may need a separate primer coat depending on the type and condition of the substrate (rust-proofing, anti-absorption, etc.).

- *Any repairs to fragile substrates, cracking, or other areas are required separately.

Each square meter of AMI COAT contains 100,000 fibers that provide flexibility.

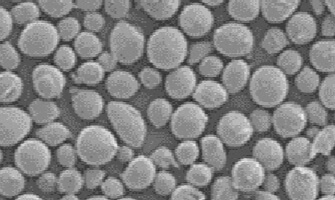

Silica balloon nanoparticles are natural ceramics. This material thickens the paint and enhances durability.

Specialty resins protect surfaces with paint containing a barrier for titanium oxide that controls radicals*, hindered amine light stabilizers (HALS), anti-algae/mildew properties, and anti-static monomer blends for long-term protection.

*Radicals are a substance generated when titanium oxide contained in paint is exposed to ultraviolet rays and degrades the paint film.

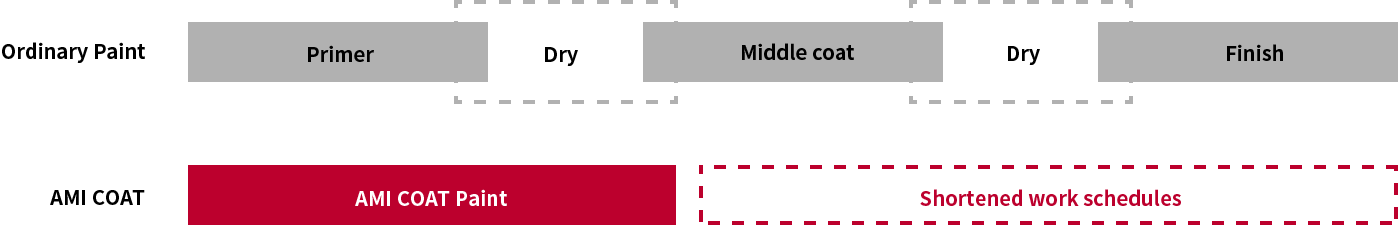

Final coatings of paint must adhere to surfaces and ensure durability and concealment. AMI COAT shortens work schedules by integrating these properties into a one-step painting process with our formula nearly twice the thickness of ordinary paint.

Ordinary paints are especially time-consuming with the need for extra coats and interspersed times for drying between each coat.

Work schedules may be extended even further when painting exterior walls and roofs depending on the regional and seasonal weather.

Shorter work schedules mean cost saving and less impact on the lives of residents (e.g., in cases of restricted use of balconies during construction periods) when undergoing residential painting. As a water-based paint, AMI COAT is low-odor. The water-based formula allows for curing removal immediately after painting.

2.Top class heat reflection performance in Japan

AMI COAT contains heat-blocking pigments, making the paint one of the best in heat-reflection performance in Japan. The paint effectively reflects sunlight from the building, suppressing rising temperatures and preventing building deterioration caused by solar radiation. At the same time, it also helps cool the building’s interior.

The silica balloon nanoparticles in AMI COAT boost heat reflection performance with an added secondary thermal insulation effect.

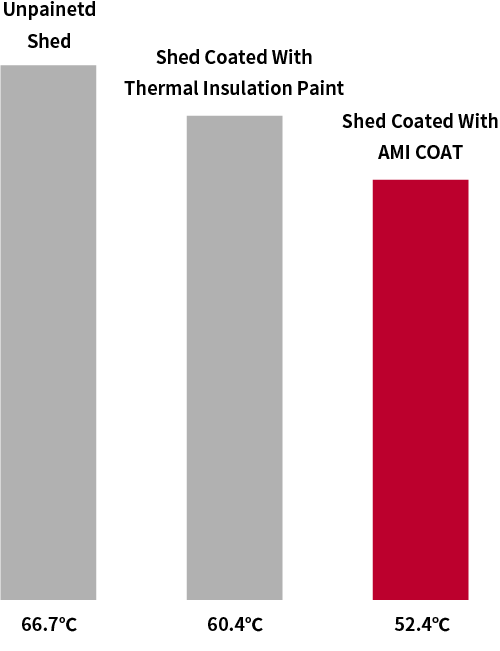

The graph on the left shows proof-of-concept test results in which we prepared identical un-painted sheds. Of these sheds, one was left bare, one was painted with a thermal insulation paint from another maker, and of the third was painted with AMI COAT. We measured internal temperature changes for each shed as they stood outside in the heat in August 2022.

The bare shed reached a high of 66.7°C, the shed with thermal insulation paint reached a high of 60.4°C, and the AMI COAT-painted shed reached a high of 52.4°C. AMI COAT paint recorded 14.3°C lower than the bare shed and 8°C lower than the shed painted with thermal insulation paint.

3.Long-term building protection with AMI COAT

A single coat of AMI COAT paint is unbelievably durable. Despite lower labor hours, a single coat offers long-term protection for buildings that inhibits deterioration caused by climate, wind, rain, UV rays, and algae and mold growth.

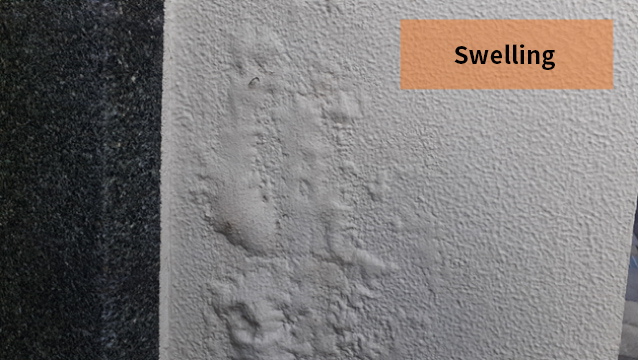

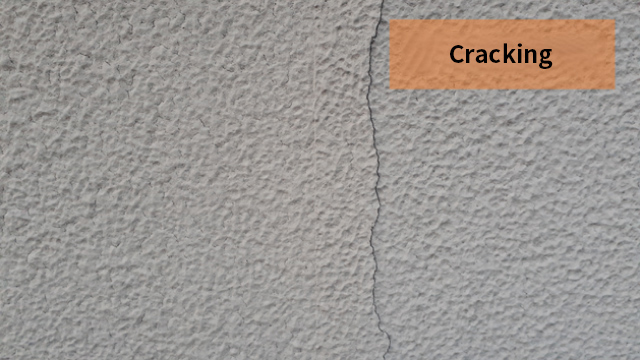

AMI COAT even prevents swelling with its moisture permeability. Special fibers in the formula reinforce the wall surface to prevent cracking.

Thick film and radical control

4.One-coat process greatly reduces the risk of working at heights

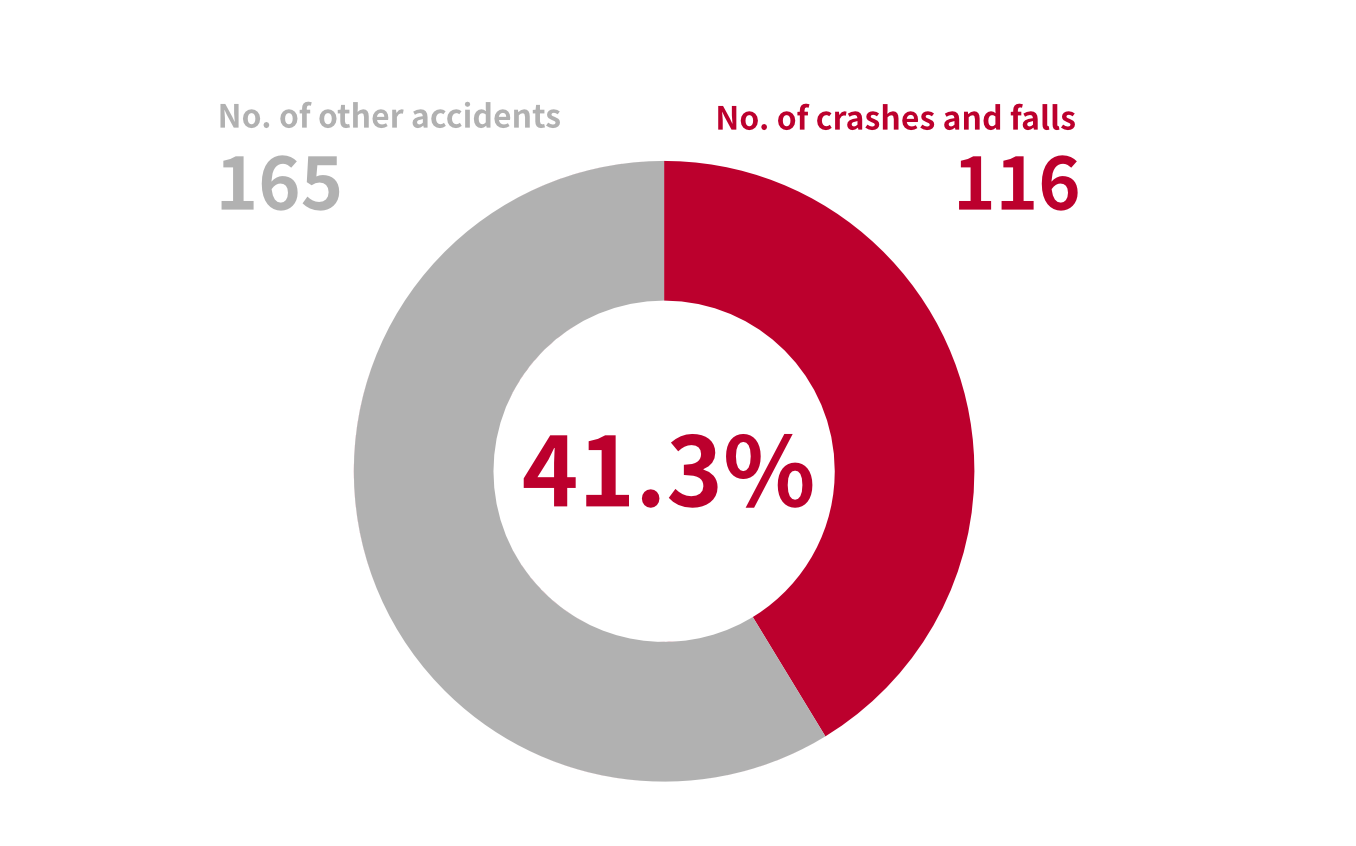

The majority of fatalities and accidents at construction sites are caused by crashes and falls from high areas.

As mentioned above, most ordinary paint requires three coats. This is no different for high areas, which is extremely dangerous.

AMI COAT produces a finished product with a single coat, regardless of the base material. Therefore, AMI COAT reduces the risk of painting high areas to about one-third than that of ordinary paints.

5.Covers composite materials, expanding into various other possible fields of paint

AMI COAT paint provides a finished coating on composite materials without the need for a primer. This feature is effective for buildings such as houses, stores, and factories, as well as buildings in numerous other fields.

For example, AMI COAT is compatible with a wide variety of structures and sites, including railroad overhead lines, high-rise multi-story parking garages, wind turbines, gas tanks and containers, ships, and automobiles.

Exclusive Option to Maintain a Longer, More Beautiful Appearance

Topcoat made exclusive to protect the beauty of AMI COAT

Dust Barrier 2

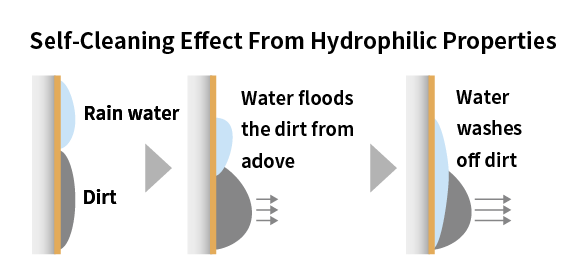

Applying the Dust Barrier 2 topcoat to the finished coat of AMI COAT generates self-cleaning properties.

While AMI COAT is highly durable, dirt may adhere to the surface over time and deteriorate the paint. Applying Dust Barrier 2 prevents dirt-derived deterioration.

Applying Dust Barrier 2 to the finished coat of AMI COAT creates a hydrophilic surface. Rainwater spreads thinly over the surface of coat and washes off any dirt.

We conducted a dirt-resistance experiment using Dust Barrier 2 and hydrophilic low-staining paint. In this experiment, we sprayed a mixture of carbon and resin on each surface to resemble dirt. Then, we poured water on each surface from a watering pot to mimic rain. We repeated this process five times.

The surface coated with hydrophilic low-staining paint retained dirt after repeated application, while the water on the surface coated with Dust Barrier 2 cleared away any remaining dirt.

Proud Manufacturer: Matsue Paint Co., Ltd.

Strength and kindness for society and the environment

We established Matsue Paint to sell paints and peripheral equipment.

In 2000, we began developing paints that offer long-term protection for buildings. We are committed to reducing the impacts of paint on the environment and, above all, on people.

We invented AMI COAT to improve recent working environments. Many corporations and construction companies rely on AMI COAT for its durability, advanced heat-reflection properties, and the ability to shorten work schedules.

We will continue to develop paint to create even better options for people and the environment.

Click photos to enlarge

Company profile

| Company name | Matsue Paint Co., Ltd. |

|---|---|

| Home page | http://matsue-paint.co.jp/ |

| Outline of business | Wholesale and manufacturing of paints and other products |

| Date of establishment | 1971 |

| Capital | 20 million yen |

| Number of employees | 7 |

For inquiries, please contact Overseas Expansion Support Office, Shimane Prefectural Government: kaigai-tenkai@pref.shimane.lg.jp